Introduction

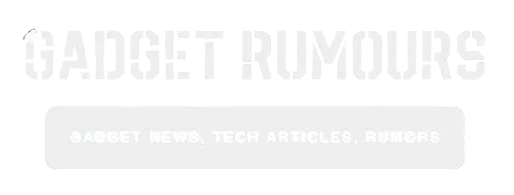

If you’ve ever tried engraving metal — whether it’s a company logo on a stainless-steel tool, a serial number on a part, or a name on a piece of jewelry — you know how important precision and durability are.

Over the past few years, fiber laser engraving has completely changed the way professionals approach metal marking. It’s faster, cleaner, and simply more reliable than anything that came before it.

Let’s break down the five biggest reasons why fiber lasers have become the go-to technology for anyone serious about quality engraving.

1. Accuracy that Stays Consistent

A fiber laser doesn’t just engrave — it etches perfection.

The beam is so fine that it can mark microscopic details like barcodes or QR codes on metal parts without losing clarity. Unlike mechanical tools that wear down, the laser’s precision remains the same for years. Every piece comes out identical — whether it’s your first or your thousandth.

2. Speed That Boosts Productivity

Time is money in manufacturing, and fiber lasers deliver results at incredible speed.

They can engrave up to ten times faster than older systems, making them ideal for both mass production lines and custom workshops.

When combined with CNC automation or conveyor setups, fiber lasers can run all day long with minimal supervision — no wasted motion, no downtime.

3. Works on Practically Any Metal

One of the main reasons people fall in love with fiber lasers is their flexibility.

They work beautifully on stainless steel, aluminum, brass, copper, titanium, and even gold. You can create permanent markings on tools, machine parts, or high-end personalized products.

👉 For example, at CNCLaserDeals.gr you’ll find professional fiber laser machines used by both industrial manufacturers and creative studios that engrave everything from ID plates to custom jewelry.

4. Low Maintenance, High Efficiency

Unlike CO₂ lasers or mechanical engravers, fiber lasers don’t need mirrors, lens replacements, or gas refills.

They’re built to last — solid-state machines that can operate for 100,000+ hours with almost zero maintenance.

They also consume far less electricity, which makes them both eco-friendly and cost-effective in the long run.

Many small businesses in Greece have already switched to fiber lasers because they simply run smoother and pay for themselves within months.

5. Permanent Results That Look Beautiful

Metal engraving isn’t just about leaving a mark — it’s about leaving the right mark.

Fiber lasers create permanent, corrosion-resistant engravings that can handle heat, friction, and chemicals.

The contrast on materials like stainless steel or anodized aluminum is stunning, giving your products a sharp, professional finish that stands out.

Conclusion

Fiber laser engraving has quickly become the standard for modern metal marking — combining precision, speed, and reliability in one compact system.

Whether you’re running a manufacturing facility or a small creative shop, investing in a fiber laser will save you time, reduce costs, and take your product quality to the next level.

👉 You can explore professional fiber laser engraving systems at CNCLaserDeals.gr — one of Greece’s most trusted suppliers for high-performance laser machines and CNC equipment.

Read Also: How CO₂ Laser Cutters Are Transforming Modern Manufacturing and Design

Leave a Reply